Designing 3D printed objects is a crash course in industrial design. Turning an idea into a thing that does a job is a major skill. That’s why you can get a degree in Industrial Design. Over the years I’ve had more “oh, crap” moments at the design stage than I can count. Once you get past those, there’s a bunch more to deal with when you actually try to make the print, especially in FDM and SDM where trying to print in thin air rarely works out. And then you get to it prints but it breaks / doesn’t do the job / solves the wrong problem and go back to CAD.

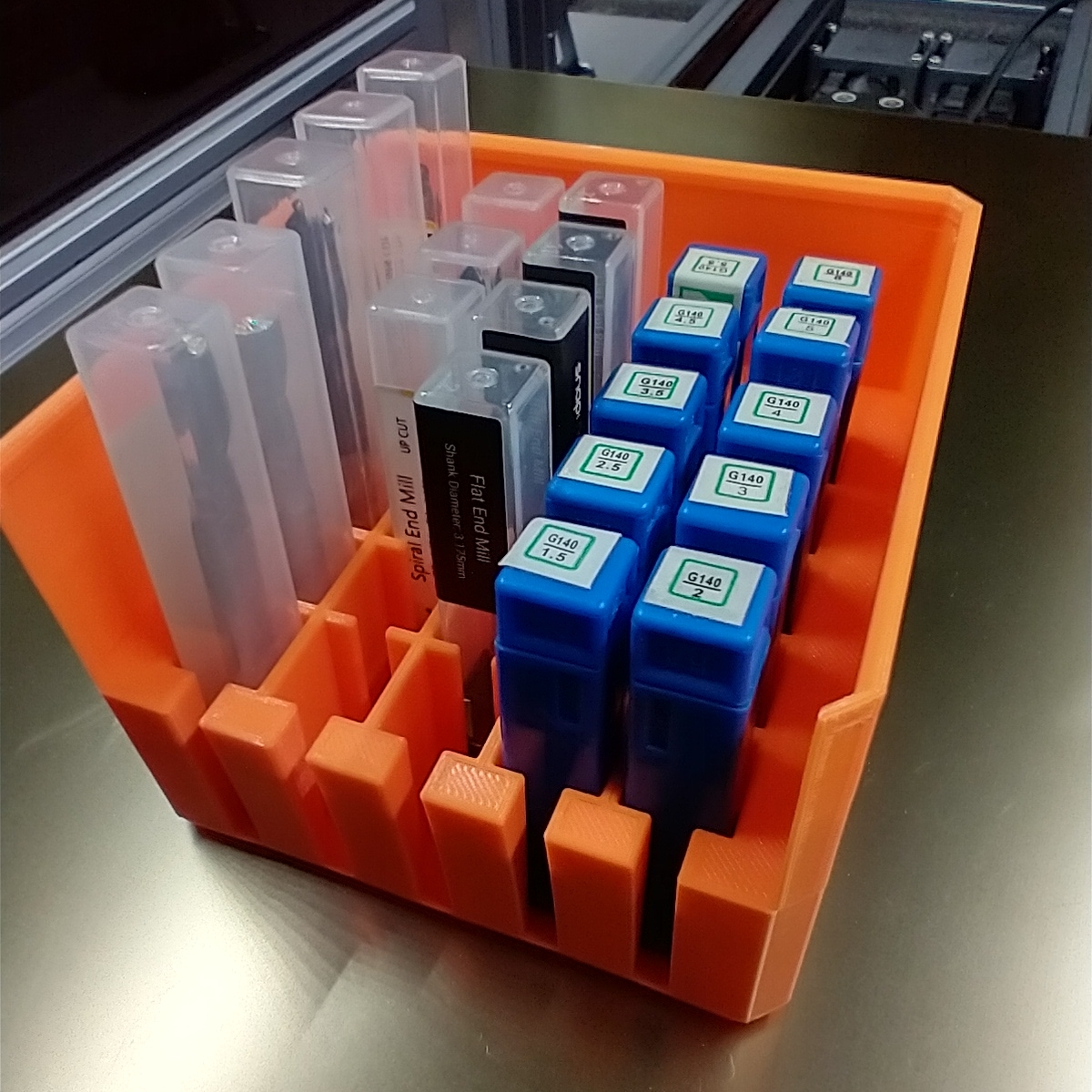

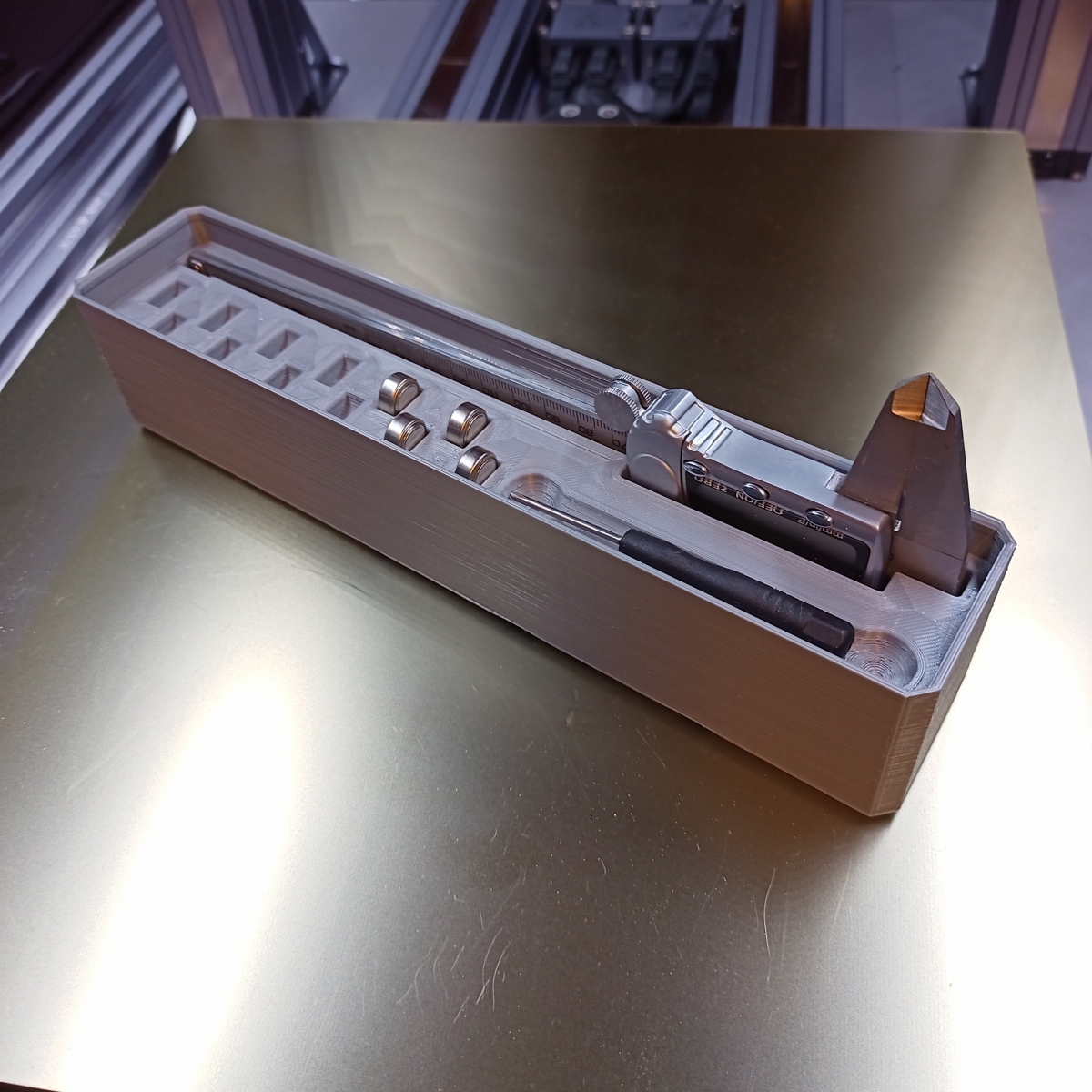

The router bit module brief is simple enough: make a module that keeps many bits together, makes the bits accessible, uses as little space as possible, and can be stored away to save workspace real estate.

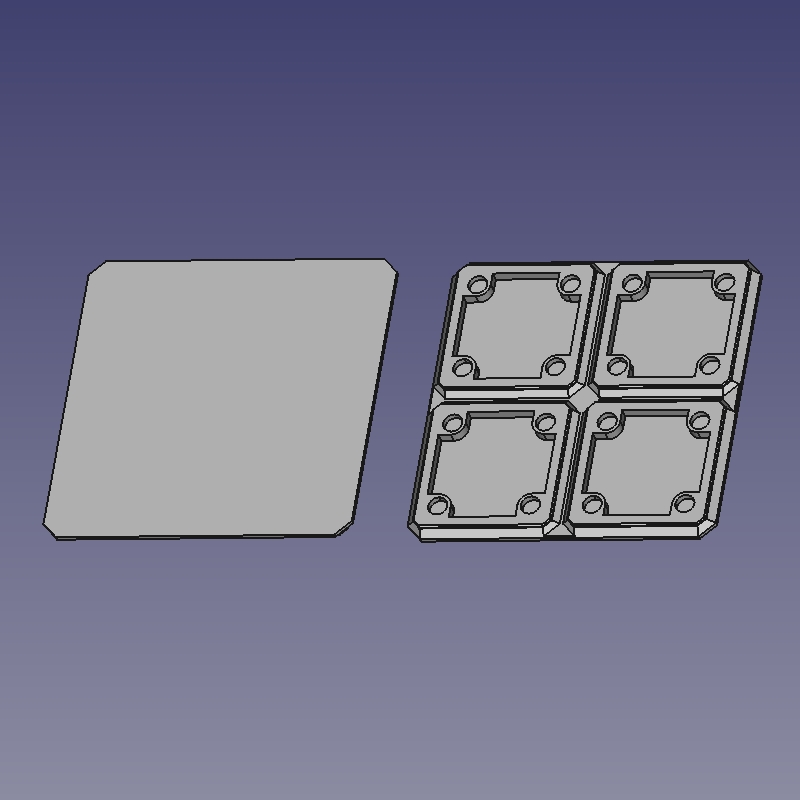

In an ideal world, every FreeGrid module could be enclosed on five sides and easily stacked. Given that only the front is open, a lid with a grid pattern on top would make it possible to create relatively stable towers of modules. In a tight workspace, organized stacking is something I anticipate will be necessary.

I was trying to achieve this for the router bit module. Each of the bits is contained in a case. In order to support a lid the module’s walls need to clear the tallest case, which is in the order of 85mm. Add in space for the floor and overlap between modules, this would require a box that’s 100 mm high. Meanwhile, the smallest cases are in the order of 55 mm tall. Getting a short case out of such a tall box could be tight, and thus not easy. Not easy is not good.

Not to mention that the print time and filament used in printing those tall blank walls adds to the cost. The tall unsupported walls are likely prone to damage and flexing too, which could have a negative effect on stackability. Is there a benefit that justifies that cost? Not really. Some kind of compromise is required.

Enter a version with “medium” height walls. Too short to contain the tallest cases, but more than adequate for 70% of the bits. Not a bad compromise, maybe a smaller tall-wall version for the tall bits and the medium one for the bulk of the bits. Or maybe the tall one can angle the cases back more, increasing depth but reducing height. Reverse the incline so they all present their noses at the front. You can see the bit and get it in or out pretty easily.

Or give up on the ideal world scenario. Drop the walls to a minimum, let all the bits poke above that level, sacrifice stackability. Ease of access is maximized and a bit could be 200 mm high and still be accommodated. Print times and filament use is optimized too. This looks like the best compromise even though it’s throwing out a major requirement…

This might be the best solution but it’s hardly satisfying.

Time for some “still in the box” thinking. These tall walls are only required if the module is going to be stored in a stack. So why not create tall lids that can be used as spacers. These could be optimized to reduce print time and material use, and aren’t specifically reserved for this module either. Closed on four sides, the spacers will offer more protection than a three sided alternative. Maybe the can have a lattice structure so it’s still possible to see what’s inside, too.

So that’s where I’m going with this. Low profile, with options.

Please help support FreeGrid development by giving any amount to us via Liberapay .